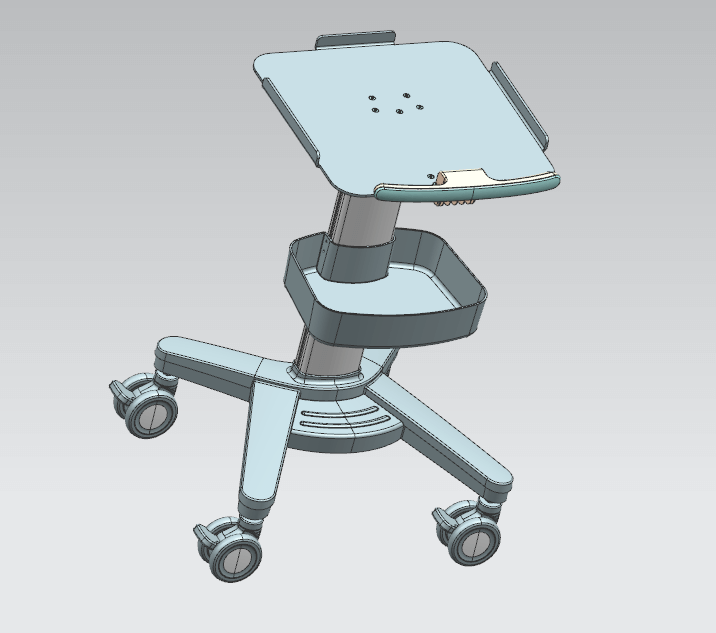

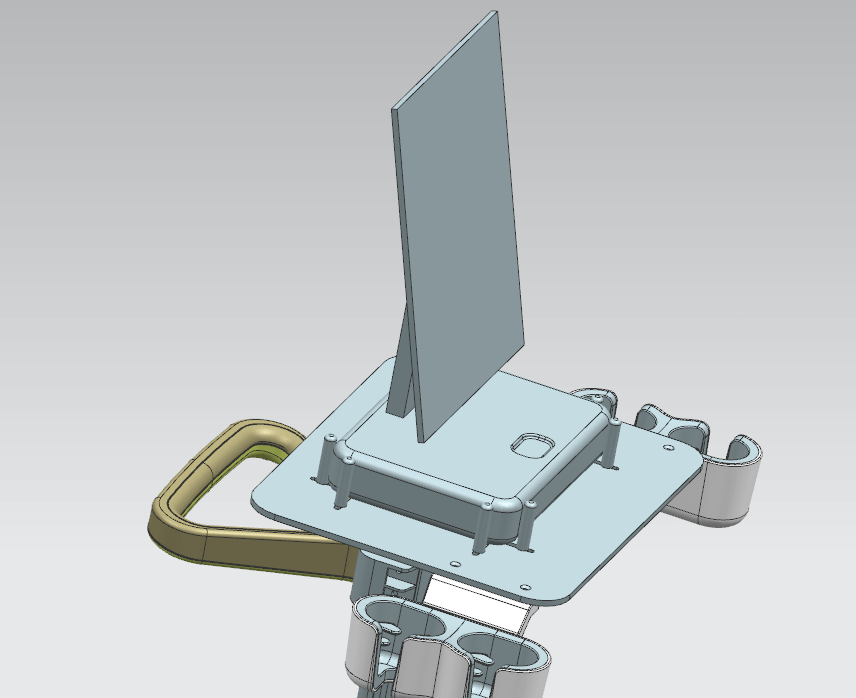

MB102 Ultrasound Cart with Fully Customizable Panel

Product Positioning

As the core highlight of the MB102 series, its full-dimensional panel customization capability truly allows this compact ultrasound cart to achieve "one cart, a thousand configurations." We deeply understand the unique needs of different ultrasound devices and various departmental workflows. Therefore, panel customization has been developed as a core value and specialized feature of this product.

Customization Dimensions Detailed

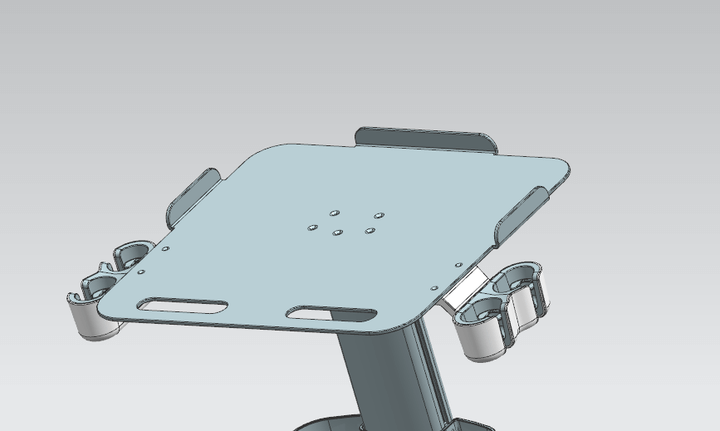

1. Size Customization

-

Standard Size: 385×340mm panel

-

Extended Range: Supports any rectangular size within 300×300mm to 450×400mm

-

Special Shapes: Accepts non-standard shapes such as L-shaped or trapezoidal panels (device layout drawing required)

2. Drilling Layout Customization

3. Material and Surface Customization

-

Base Material Options:

-

Standard: 1.5mm thick aluminum alloy sheet

-

Reinforced: 2.0mm thick carbon steel sheet (40% increased load capacity)

-

Lightweight: Composite honeycomb panel (35% weight reduction)

-

Surface Finishes:

-

Medical-grade powder coating (standard white/blue/gray)

-

Antimicrobial coating (optional)

-

Anti-static treatment (suitable for high-precision equipment)

-

Matte/gloss effect is optional.

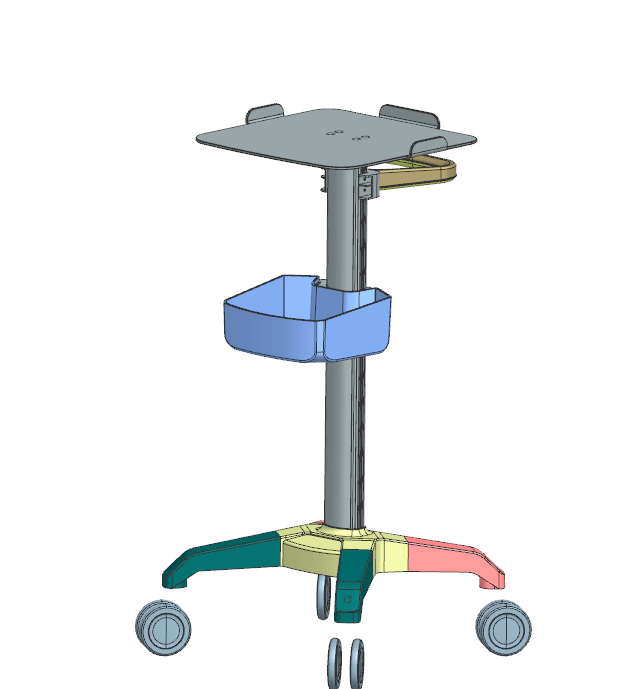

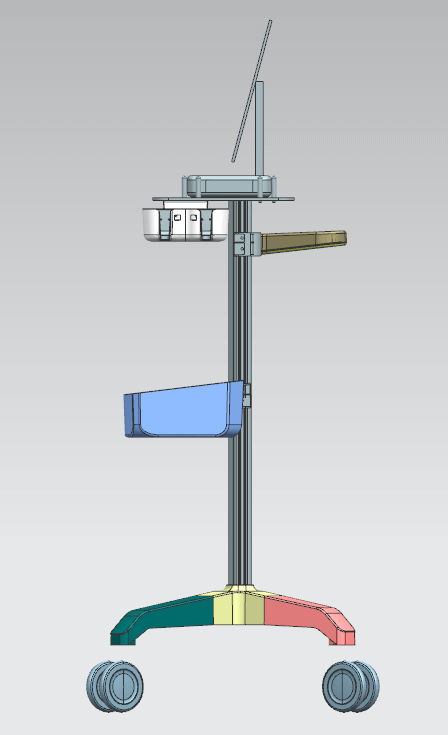

4. Functional Zoning Customization

【Example Layout A: High-Efficiency Examination Type】

┌─────────────────┐

│ Equipment Fixation Zone │ ← 4 precision positioning holes

├─────────────────┤

│Cable Management Slot Holder Position│ ← Hidden cable routing + 2 probe holders

└─────────────────┘

【Example Layout B: Teaching Demonstration Type】

┌─────────────────┐

│Device Zone │ Tablet Mount│ ← Integrated device + auxiliary display

├─────────────────┤

│ Keyboard Tray │Supplies Zone│ ← Pull-out keyboard + gel holder position

└─────────────────┘

Customization Process

-

Requirements Collection (1 business day)

-

Solution Design (2-3 business days)

-

Production & Manufacturing (5-7 business days)

-

CNC precision machining

-

Surface treatment

-

Quality inspection

-

Fast Delivery (2-3 business days)

Why Choose Our Customization Service?

-

Precise Matching: Not "good enough to work," but "perfectly fitted"

-

Fast Response: From requirement to delivery, as fast as 10 business days

-

No Hidden Fees: Custom quote includes the entire process: design, machining, surface treatment

-

Ongoing Support: Lifetime hole modification service (material cost only)

-

Quality Assurance: Custom panels come with a 3-year warranty